Now, an inline-6 engine is heavy, to the tune of several hundred pounds of cast and machined steel, but the clutch, flywheel, and clutch housing, which sits between the now-removed transmission and the engine block, adds probably another seventy pounds and has to come off. The engine cannot be mounted of the engine stand until the clutch housing comes off. I am backtracking here, because in my previous post I showed you that the clutch housing was removed and the engine is on the stand. This is that process.

That starter has to come off first. The starter is an electric motor which spins the flywheel, which turned the pistons and allows the internal combustion cycle to start. The images below show the starter in place on the passenger side of the engine. Curiously, the lower bolt has been replaced with one too long and shimmed by a stack of washers.

As you can see, it was a simple matter to extract the two mounting bolts and pull off the starter motor. That gives me a new serial number for my tally sheet.

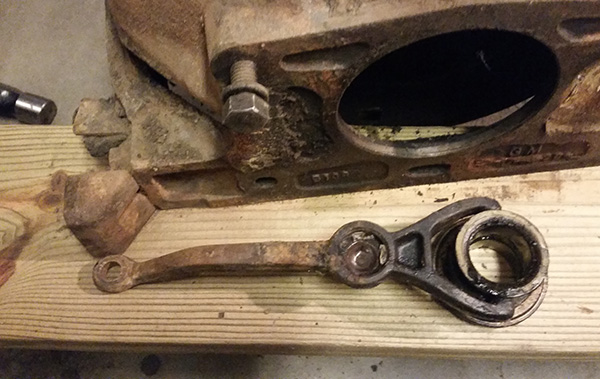

The first thing removed is the clutch fork and throwout bearing. They simply lifted out with a bit of wiggling through the available space.

Once the starter was filed in my growing pile of parts, the clutch assembly has to be dropped. That involves a dozen bolts around the edge, bolting the clutch to the flywheel. That requires working from the underside. I had previously pulled the clutch cover, which amounted to only a couple of bolts.

Here is the assembly, posing on the garage floor (no, I didn’t drop it).

The clutch assembly will likely have to be replaced, but I’ll have someone who knows more than I do tell me whether that is positively so. I’d like to keep everything original to the truck, but good sense may dictate that Green needs a new essential element. Discretion, y’know.