With the manifold off, I’ve reached a point in disassembling the engine that the really big stuff has to be faced. This step involves removing the head from the block.

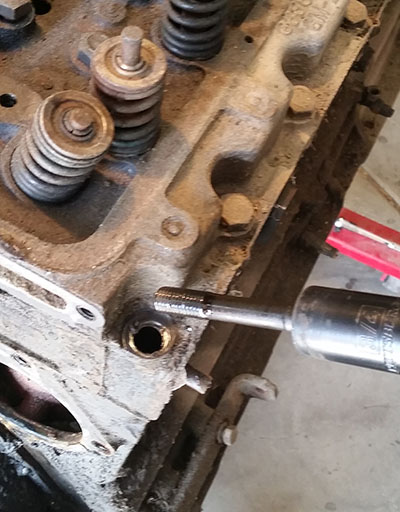

Removal of the first bolt, driver’ side front.

There are twenty bolts of varying lengths running along either side, one between each cylinder plus two at either end. These are torqued to specific pressure so that the head unit is held down evenly across the surface of the block. Two of the bolts (well, more than two) came out when I installed the lift chain to remove the motor from the chassis, but the rest are ready to come out now.

I’ve set them back in place to keep them in order.

With all the bolts loosened, the head did not simply lift off. A few good whacks with the dead-blow mallet were required to break the seal between the two parts and the gasket.

As you can see, each of the bolts gets bagged in its group and filed in my growing pile of parts.

The head itself is a casting, with the added weight of sixteen valves and springs. A cursory examination suggests that the head is in good shape. I could not see any obvious crack that would require replacing the head, but the head will be checked by the machinist for sure.

The intake and exhaust valves for the sixth cylinder, showing carbon buildup.

As I’ve explored the automotive mysteries I’ve learned that the valve seats in the head will require attention. They have to be hardened to deal with the temperatures generated by the present mixture of the unleaded gasoline formulated today—a hotter-burning E85 gasoline-ethanol mixture. That will be part of the job of the machinist; I’ve just got to get everything into their hands.